|

Preparation

Like all figures, there will sometimes be a small raised line where the two halves of the mould fit together. To make the models look their best before painting, you will want to clean these off. The easiest way is to carefully trim off any visible mould lines using a sharp hobby knife.

For advanced modellers who like doing conversions, head swaps etc, you can slice, drill or otherwise cut up the flexible plastic just as you would with hard plastic.

The flexible plastic can sometimes be bent in the packaging — gun barrels and other thin parts are prone to this. If any of your models have bent parts, you can dip them in hot water for a few seconds to straighten them out. The parts have a ‘memory’, and will usually instantly spring back to straight as soon as they contact the water. If not, just heat the part gently in the water, then straighten it out with your fingers for a few seconds while it cools.

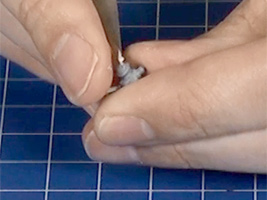

Gluing

We recommended using superglue (aka cyanoacrylate) to flexible plastic figures. Plastic cement, which works by chemically softening the hard polystyrene plastic, will not work (the new figures are an ABS plastic, which does not react chemically with the plastic cement). Superglue gives a strong bond with the flexible plastic, whether you are gluing the figures to their base, doing minor conversions, or attaching parts to other materials (eg. glue crew figures into vehicles, whether they are hard plastic, resin or metal).

|

|