|

|

|

|

Products mentioned in this Article

--None--

|

|

|

|

|

|

|

|

|

|

|

|

|

A History of the T-34

Part II: T-34 obr 1941 variations and T-34 obr 1942

Part I...

During the first half of 1942 T-34 production was restricted to just three plants.

• Factory No.112 Red Sormovo Works (in Gorki).

• STZ (Stalingrad Tractor Factory).

• Factory No.183 Ural Rail-Car Factory (UVZ) (in Nizhni Tagil)

|

Each of these factories overcame various problems in their own way to make sure T-34 production continued. The Red Sormove factory used artillery shells to make compressed-air tanks for the engine starting mechanisms.

The Stalingrad factory used their extensive casting facilities for the production of turrets and hulls instead of welded or stamped parts. As rubber supplies dwindled rubber rimmed road wheels were replaced with all steel examples.

|

|

|

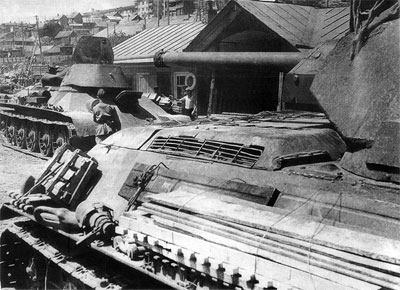

Above and right: STZ T-34 obr 1941 showing the large plate at the rear of the turret.

|

|

|

Production at STZ continued even as the Germans closed on the city, but on 5 October 1942 the order to evacuate was finally given and production stopped.

To compensate for the lost of production at Stalingrad a new tank factory was set up in Chelyabinsk Kirov (ChKZ) industrial complex. The first T-34s rolled of the factory floor on August 22.

• Factory No.100 Kirovskiy Works in Chelyabinsk (ChKZ or Tankograd).

• In 1942 Factory No.174 at Omsk started producing T-34s.

|

|

In early 1942 a wave of panic hit the Red army over new German

anti-tank weapons like the PaK 40 and an effort was made to up-armour

many T-34s. The T-34s were fitted with appliqué armour welded to the

hull Front and turret sides.

It was soon realised that the added weight limited one of the T-34s main advantages in combat, its speed and mobility. Once it became apparent the Germans would not be producing the new guns in the numbers the Soviets assumed they would, the extra armour wasn’t added to any more tanks.

Below left: T-34 obr 1941 with all steel road wheels.

Below right: STZ T-34 obr 1941.

|

|

|

|

|

T-34 obr 1942

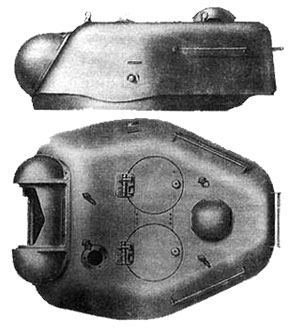

Though it was decided not to implement the T-34M as a design, some of the ideas introduced in its development were implemented. One of these was the hexagonal turret design. The new turret was slightly larger with two round hatches instead of the one large one. The extra space inside allowed for the increase of ammunition stowage, from 77 rounds to 100.

Other improvements to the T-34 obr 1942 included a new air-filter, a new five-speed gearbox and the universal adoption of the armoured hull machine-gun mantlet.

|

|

Production of the new model started in August 1942 at ChKZ and Uralmash (Ural Heavy Machinery Plant in Sverdlovsk), these two factories utilising a 5,000-ton forge-press for stamped versions of the new hexagonal turret. Other factories produced the new turrets in cast and welded form.

Initial external fuel tanks were box shaped and mounted on the back of the hull rear, but from mid 1943 round drum fuel tanks were mounted on the side of the hull.

In mid 1943 Red Sormovo Works (in Gorki) was the first factory to mount a commanders cupola on the left turret hatch. These allowed the tank commander to observe with out exposing his head to enemy fire.

The T-34 obr 1942 was made into the middle of 1944 when all production was completely switched to the T-34/85.

Next time we look at the T-34/57, SU-122 and the SU-85.... (live 15 January 2009)

|

|

Last Updated On Thursday, December 18, 2008 by Wayne at Battlefront

|

|

|